Soft Gel Line

Soft Gel Line

Description

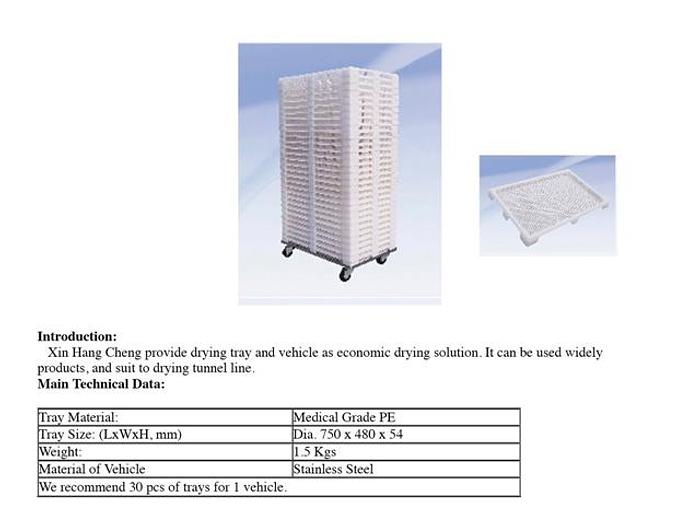

One used Complete Soft Gel Manufacturing System - Consists of Lots: MJK0413: Beijing Sinagel Gelatin Coloring Machine Model: TRTS-WR MJK0414: Beijing Xinhangcheng Ingredient Tank Type: PLG-I-500 MJK0415: Hatco Corp. Electric Water Heater Tank Capacity: 19 Gallons MJK0416: Bio Reactor with Gelatin Melter and Mezzanine MJK0417: Thermal Gelatin Service Tank 200 L MJK0418: Thermal Gelatin Service Tank 200 L MJK0419: Beijing Xinhangcheng Glue Kettle GJT-200 L MJK0420: Beijing Xinhangcheng Glue Kettle GJT-200 MJK0421: Soft Gel Extractor MJK0422: Beijing Xinhangcheng Centrifuge Model: 600 MJK0423: Soft Gel Machine MJK0424: Drying Tumblers Type: SGJ-II 38 Drying Tumblers MJK0425: Soft Gel Drying Trays MJK0426: Inspection Table with Light Soft Gel Encapsulation Machine Specifications: Max rotating speed of rolling mould: 8 RPM Speed-regulating Manner: AC variable frequency stepless speed regulation Loading Difference: +- 2% Power Supply of Motor: 2/N/PE 480V, 50/60Hz Motor Power: 1.2Kw Motor RPM: 2000 Heating Tube Power: 400Wx6 Heating Jacket Power: 100W Dimensions: 2200x890x2100mm Weight: 1300Kg General Information The Softgel Encapsulation machine is integrated the latest global encapsulation technology and our gelatin encapsulation experience. The production capacity is extremely large productivity (The largest in the world.) The softgel machine has a sensitive and high accuracy positive displacement pump which delivers the fill material into a heated wedge which sits between rotary dies. This wedge injects the fill material into die cavities between ribbons just right before the die rolls cut the ribbons and seal the two halves together. The cool, dry air congeals the gelatin as the drum rotates so that a tacky, elastic band rolls off of the other end. This thin band is then automatically formed into capsules; filled with medicine, vitamins, or other products, sealed, and dropped into a tray. Xin Hang Cheng manufacturer various of high quality mould roller for Softgel Encapsulation Machine. Xin Hang Cheng’s mould rollerin high accuracy and long term using life. Moulds: 14 Sets of Moulds Made in a highly accurate CNC Processing Center to ensure they keep the high accuracy of the mould roller and can process complex shape mould cavities. Advantage surface hardening technology is used to keep the hardness and long-term usable life span of the moulds. Roller Dimension: 10" Length With multiple size dye for machine, oblong and oval shape Oblong 20 34x7 installed on the machine Website: https://softgeltech.en.ecplaza.net/products/softgel-encapsulation-machine_2546987 Location: Dallas, Texas Soft Gel Line

Specifications

| Year | 2000 |

| Condition | Used |

| Inventory # | 10982 |