Viking Masek ST1200 Stick Pack Machine

Viking Masek ST1200 Stick Pack Machine

Description

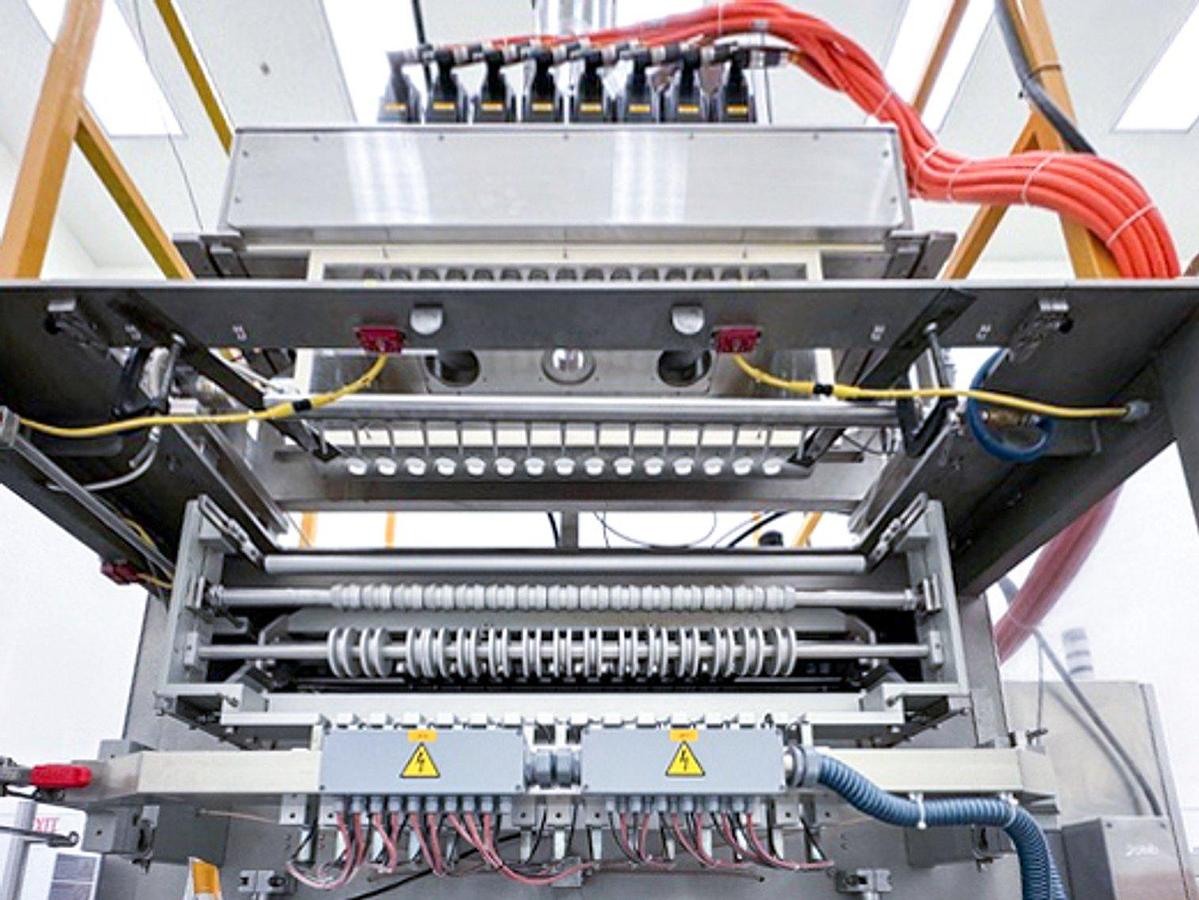

Viking Masek ST1200 Stick Pack Machine

MDL: ST1200

Electrical requirements - Standard 480V, 3 phase, 60 Hz (AB)

Pneumatic Requirements - TBD/CFM@ 90PSI of clean, dry air

ST1200 configured for twelve (12) lanes of:40mm stick packs (90mm pitch, 1080mm web width) Set of operators manuals

Allen Bradley, Servo, Festo Pneumatic

10” AB HMI

Servo Upgrade Allen Bradley, servo jaws with horizontal end seal pattern and servo film draw down Remote diagnostics modem for remote access to the machine program

Stainless steel upgrade

Straight cut across top and bottom seal, 12 lanes

Cooling Station (Air cooling without cooling jaw)

Automatic film tracking

Covers for film unwind

Individual chutes with stop gates (per lane)

Individual temperature control (per lane)

Printer Registration Bracket

Frame under ST1200 machine

Electrical and program changes for outfeed conveyor

Modification for extended stick length

Diving bridge mounted liquid filling nozzles for bottom-up filling of stickpacks

Viking Masek Green Discharge Conveyor System

Belted side discharge indexing takeaway conveyor

Two conveyor workstations

Change-Over Parts Kit

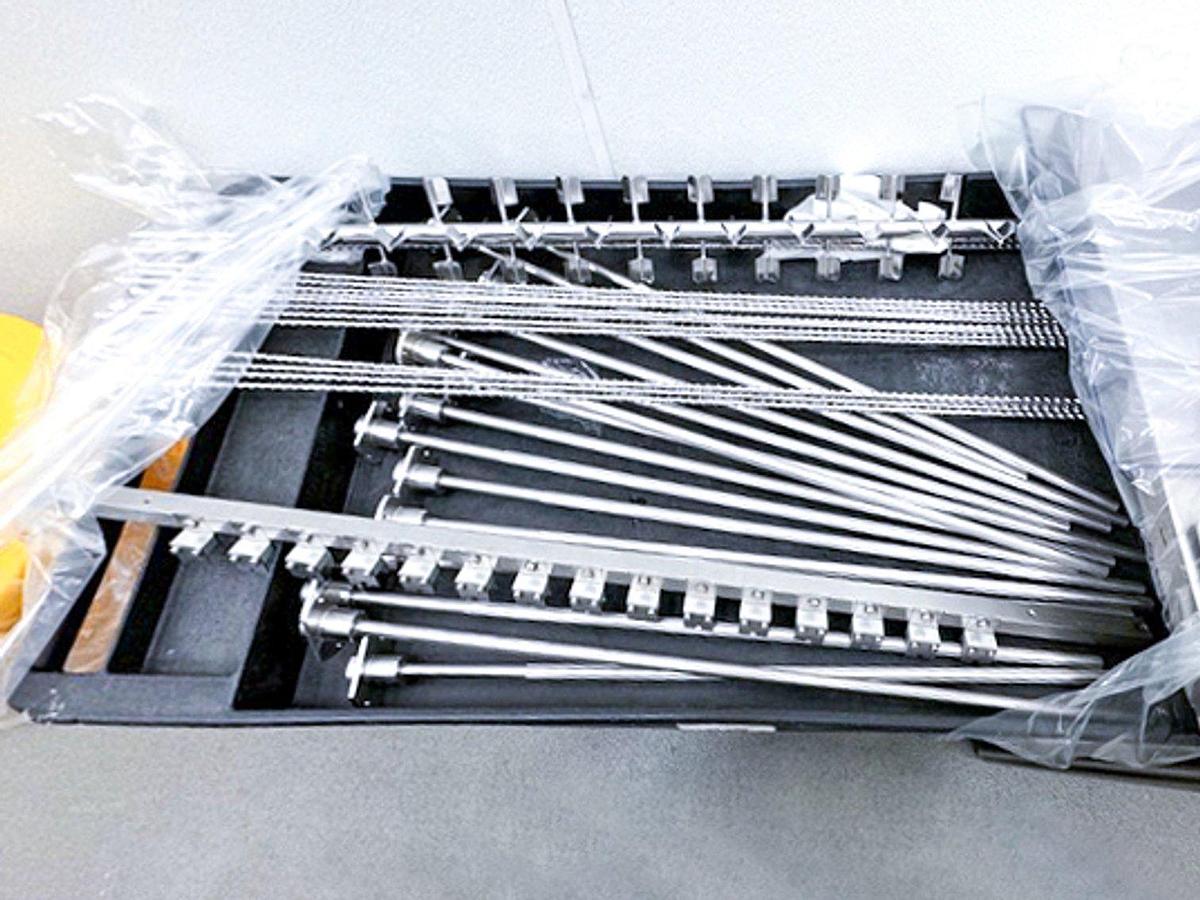

Viking Masek ST1200 Change-Over Kit (15-Lane, 23mm)

Configured for 23mm stick packs (56mm pitch, 840mm web width)

Components:

Film cutting assembly

Straight cut unit

Pour spout with tear notch

Cross jaw with air cooling

Individual chutes with stop gates per lane

Auger Filler DSO11 for 15 lanes

Allen Bradley system for auger filler control

Filler change-over system per lane

Tooling tube and forming tube hand assembly

Vertical seal bar assembly

Rail system for easy cleaning

Change-over cart included

PIAB piFLOWp Vacuum Conveying System

Type: piFLOWp, 7L capacity, 316L stainless steel

Vacuum Pump: piPREMIUM400 COAX® Technology

Seal Type: Anti-static, NBR

Filter Unit: Pleated filter, 0.5-micron

Components:

2” tangential inlet

Stainless steel air-operated actuator

ECU Pneumatic Control Unit

1/2” Main air regulator kit

Ceiling mounting bracket (304 stainless steel)

Discharge transition (rubber-coated nylon)

FlexSock 6” diameter

VideoJet 3340 Laser Marking System

VideoJet laser marking system, 3340, 10.6um, IP54 (x3)

30W marking head, SHC150C, W. beam expander, V=S.0 black (x3)

Large focusing module, F=300mm, D=48mm (x3)

US cable mains, CO2-laser, G3 (x3)

Laser light alert kit (x3)

BTU, 300mm, SCH150c, 30W straight out (x3)

AD1000 vacuum system with 100mm x 2m hose kit

PC panel with software

Suction tube system (x2)

T-nozzle with 50mm sleeve (x2)

Standard software, Smartgraph CD

Fishtail nozzle, 50mm (x4)

Large focus finder, F=300mm (RoHS)

Laser Safety Class I Certification

Laser beam shield

Features:

Uptime Advantage with laser source life up to 45,000 hours

Air-cooled laser source for reduced maintenance

High-speed marking capability (up to 150,000 products per hour)

CLARiTY™ Laser Controller for fast product changeovers and diagnostics

High-resolution marking for product traceability

Flexible integration with 32 standard beam delivery options

Multiple interface and communication options

Components:

30W marking head, SHC150C, with beam expander

Large focusing module, F=300mm, D=48mm

IP54-rated enclosure

Vacuum system with 100mm x 2m hose kit

T-nozzle and fishtail nozzle

Standard software with Smartgraph CD

Laser Safety Class I Certification

Laser beam shield

Specifications

| Condition | Used |

| Inventory # | 13035 |

| MDL | ST1200 |

| Vacuum Pump | piPREMIUM400 COAX® Technology |

| Seal Type | Anti-static, NBR |

| Filter Unit | Pleated filter, 0.5-micron |